Food Extrusion

Many food products are manufactured by the use of extruders. Cereals, breads, pasta, baby and pet food are some examples. The extruder consists of a long barrel with a mixing screw that efficiently mixes and cooks the raw ingredients and brings them to a near final or final product. Measurements of color, residence time, and product distribution are important indicators of the extruded products quality.

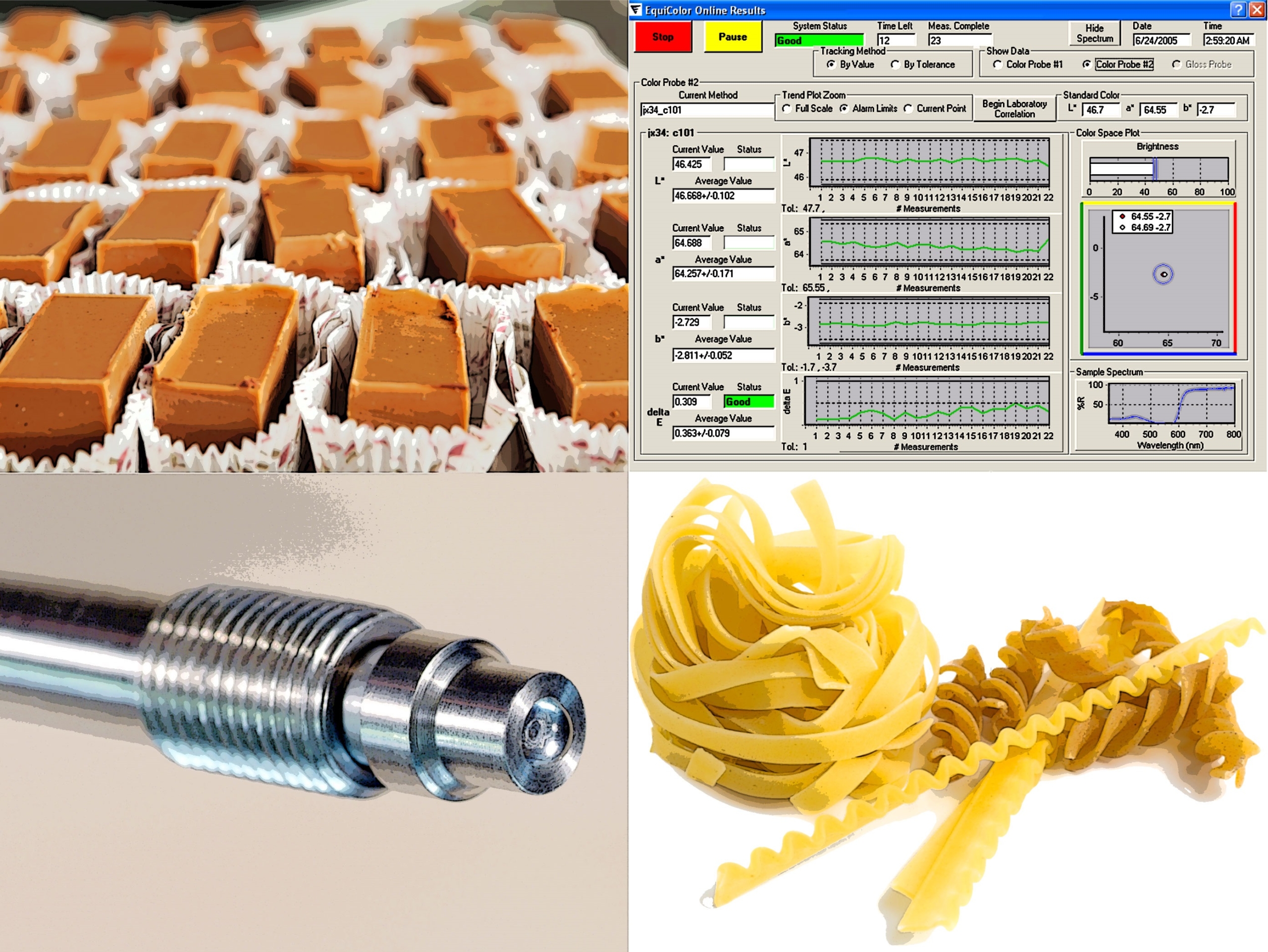

The Equitech In-Line Process Spectrophotometer (IPS) consists of an analyzer, probe(s) and software. The analyzer uses a research grade CCD for higher resolution and faster processing time. Equitech’s fiber-optic probes illuminate the sample and transport the signal back to the analyzer. Continuous real-time measurement allows for confirmation to the operator that the extruded food has a consistent color that indicates that the product has been properly mixed and cooked. Also, with the Equitech measurement, residence time (how long the food has been in the extruder) can be determined.

The typical procedure for off-line measurements:

- Manually take a sample from the process

- Send/take the sample to the laboratory

- Perform ‘off-line’ measurement in the lab

- Report the results to production

- Make a decision on a process adjustment

Repeat the above 5 steps if necessary to obtain another measurement after color corrections or after change of process parameters.

Continuous Sampling

The delay between sampling and obtaining the results from the laboratory can be time consuming. A significant disadvantage is that only a single measurement is generated in this time period and the quality of the color during before and after the sampling point is unknown.

With the in-line measurements taking place directly in the food, not only is complete documentation possible, but when color variations occur, immediate intervention can take place. This method eliminates many steps of the offline method and the measured results are available in real time.

Color Measurement of Food

Illumination of the food through the sapphire window is achieved by 6 circumferentially-positioned glass fibers which convey the light of a xenon flash lamp. The reflection from the illuminated surface is detected by one center-positioned optical fiber. This reflected light is then interpreted by the spectrophotometer. Color values such as L*, a*, b*, and others, are calculated from this spectral curve, and displayed as trend charts.

The spectrophotometer is integrated in a NEMA4 box with an industrial computer and touch screen. The spectral range is 380-780 nm (resolution 1 nm). The stainless steel NEMA4 box is designed and equipped specifically for use in the food production environment where the ambient conditions can be dusty, vary in temperature, be subject to vibration, etc. The box also contains a thermoelectric cooling and heating device to eliminate the influences from ambient conditions by keeping the temperature inside the box at a constant level.