How can the quality of the ampoules and syringes be improved?

How do you know if the thickness of the glass walls is uniform and correct?

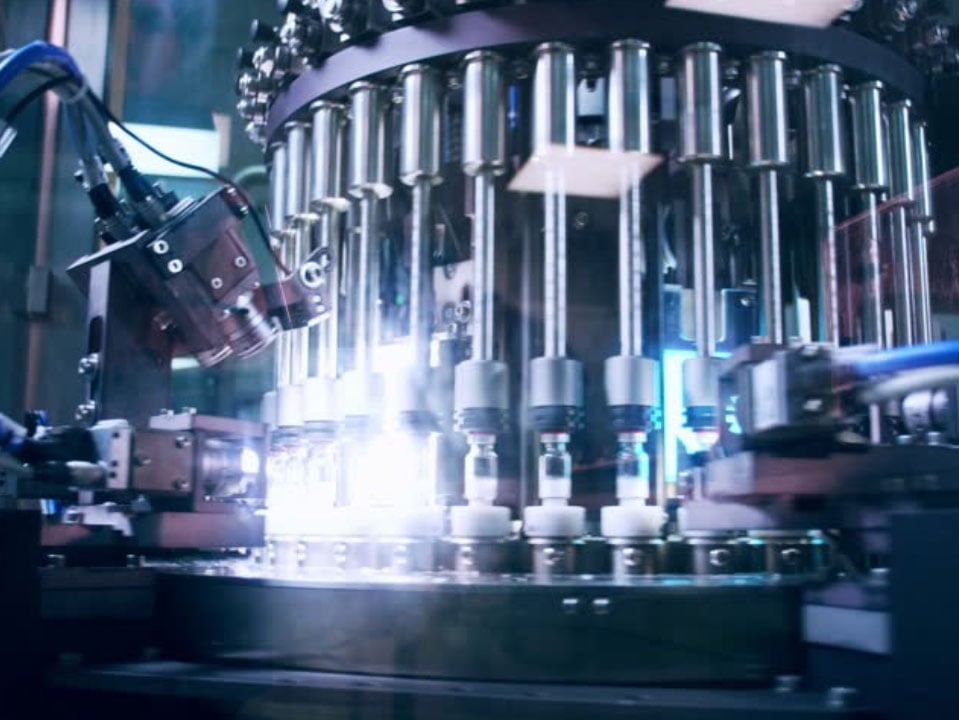

Glass vials, pre-fillable glass syringes, ampoules, and injection vials are produced by inserting long glass tubes into a glass-forming machine. The machine has multiple stations that index. The glass tubing is cut to length, and as it progresses around the stations, it is heated with gas flames and formed into many shapes using mandrels. Final product vials are approximately 25mm (1”) wide and 64mm (2.5”) long. Process temperatures are 950°C (1740°F). There are two important quality issues that need to be addressed. First, the cut edge of the vial has to be smooth to eliminate any sharp edges, and second, the vial has to have a specific shape, glass thickness, and opening to ensure the needle fit properly and the tube can be filled easily with a medical solution.

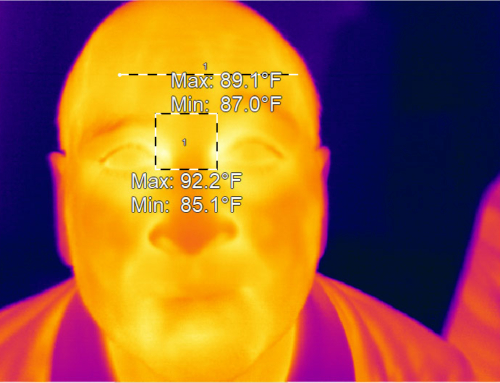

Solution and Improvements through proper temperature monitoring

The Raytek ThermoView™ Pi20 camera and DataTemp® Pi(DTPi) software allow the operator to ensure the cut lip is evenly heated around the entire lip of the glass vial and the correct temperature is achieved. As the part exits the cooling oven and passes by the camera, an image of the glass product can be taken. From this image, the manufacturer can easily detect variations in glass thickness and shape. With the DTPi software, Areas of Interest (AOI) can be set up to provide alarms to the operator if the glass vials’ thickness or shape does not meet the required specification. Each AOI can be set up with high and low alarms to automatically indicate a defective part. In addition, for quality control, a record can be kept for an easy referral at a later date, if needed. This system will improve the quality of the end product and prevent the production of defective parts.

Gx® luer lock glass syringes - Gerresheimer

Raytek Product

- RAYPi20LTMA

- ThermoView Pi20 Thermal Imaging Camera

- DTPi Software

Accessories

- XXXPi206060 Digital Input/Relay Output Module

- XXXPi206024 Digital I/O and Analog Output Module

- XXXPi20MB Mounting Bracket

- XXXPi20SWH1 5-Port Gigabit Ethernet Switch

Benefits

- Improved product quality

- Reliable temperature control

- Increased throughput

- Ability to maintain quality of product on a continuous basis